Retic Router

Retic Router (View Demo)

Retic Router is our approach to reticulation system design, automating the design process to improve operability and cost efficiency over the life of mine. The software performs dynamic hydraulic testing to quantify system reliability under real conditions. By considering thousands of potential design scenarios, we can truly optimise your system.

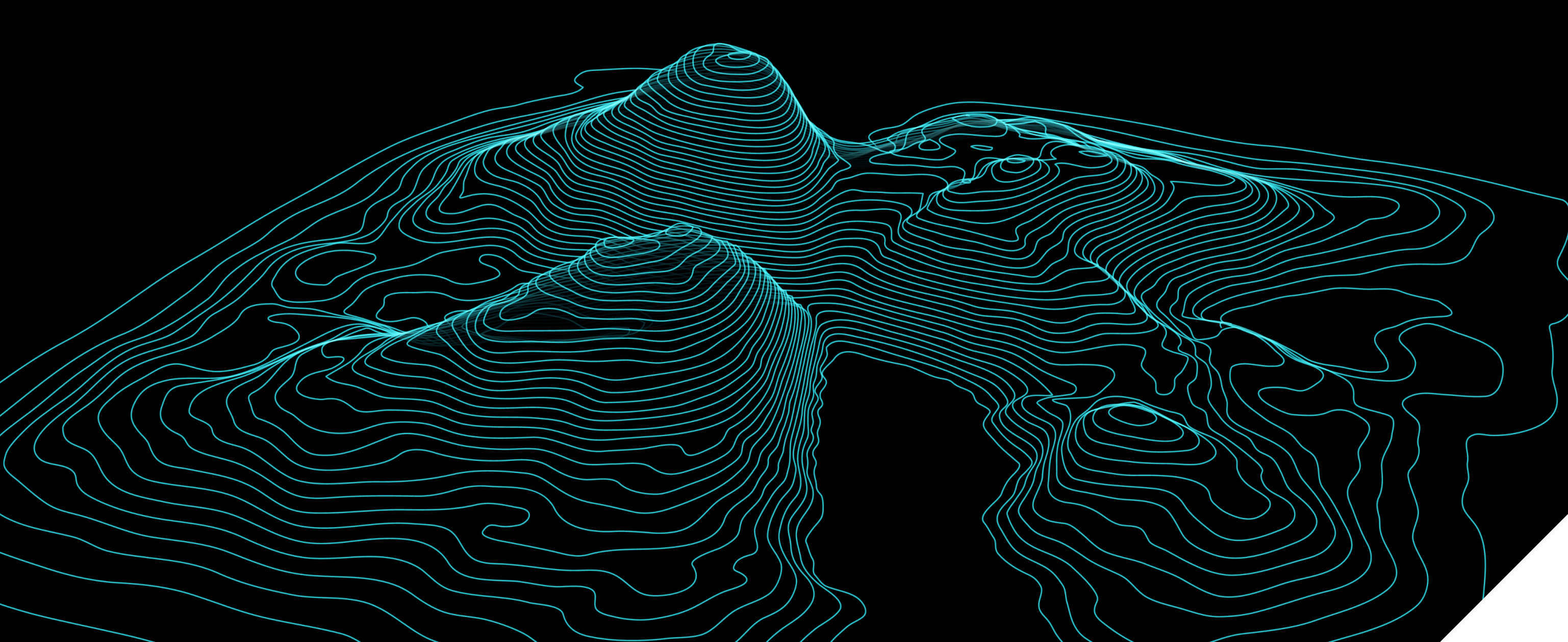

Stages of Design

- 1 Import your entire mine design...

- 2 Analyse stope solids...

- 3 Automatically develop a branched network...

- 4 Run dynamic hydraulic tests...

- 5 Generate a report with design recommendations...

Retic App

Retic App (Visit Site)

is a centralised platform for managing and optimising backfill operations...

Key Features

- Retic View - Interactive 3D visualization environment for reticulation systems, enabling

- Pipe Track - Advanced pipeline management system with wear monitoring, hydraulic performance analysis, installation scheduling, and automated generation of bills of materials

- Crush Log - Secure cloud-based QAQC database

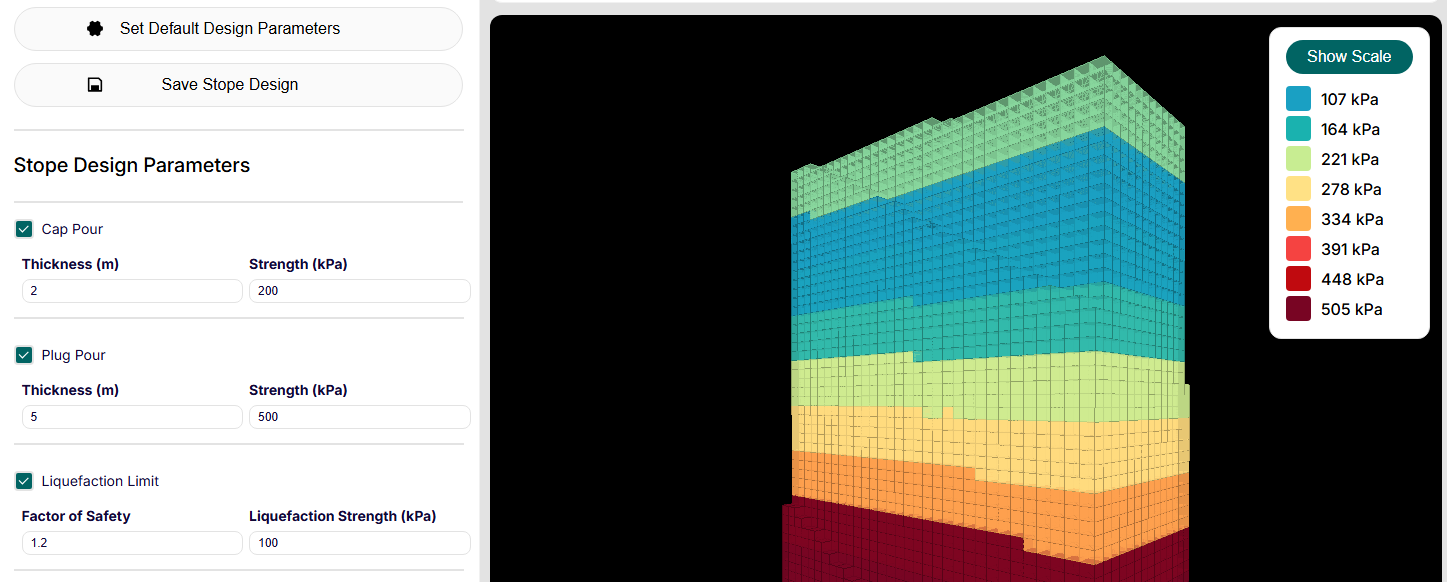

- Stope Fill - Analyse stope designs and create pour plans

- Paste Planner - Plan and schedule filling with Gantt charts

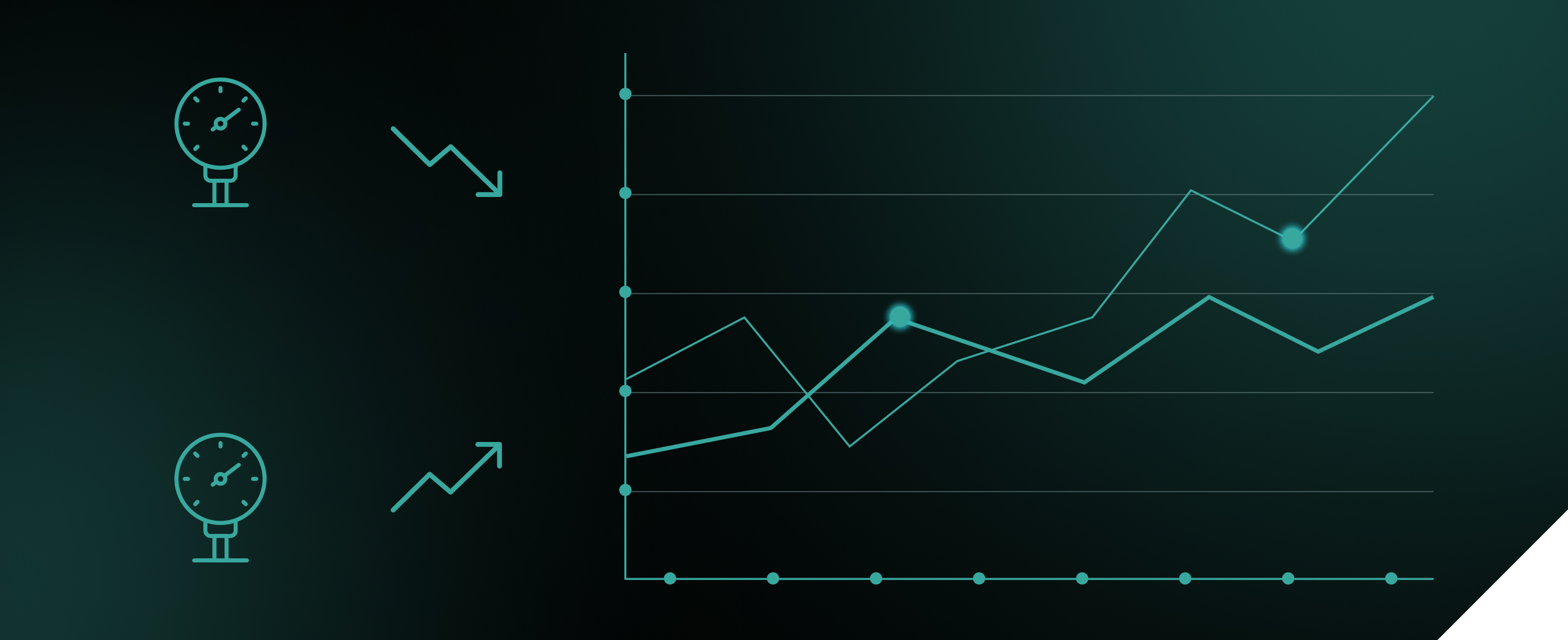

- Dashboard - Monitor performance and utilisation

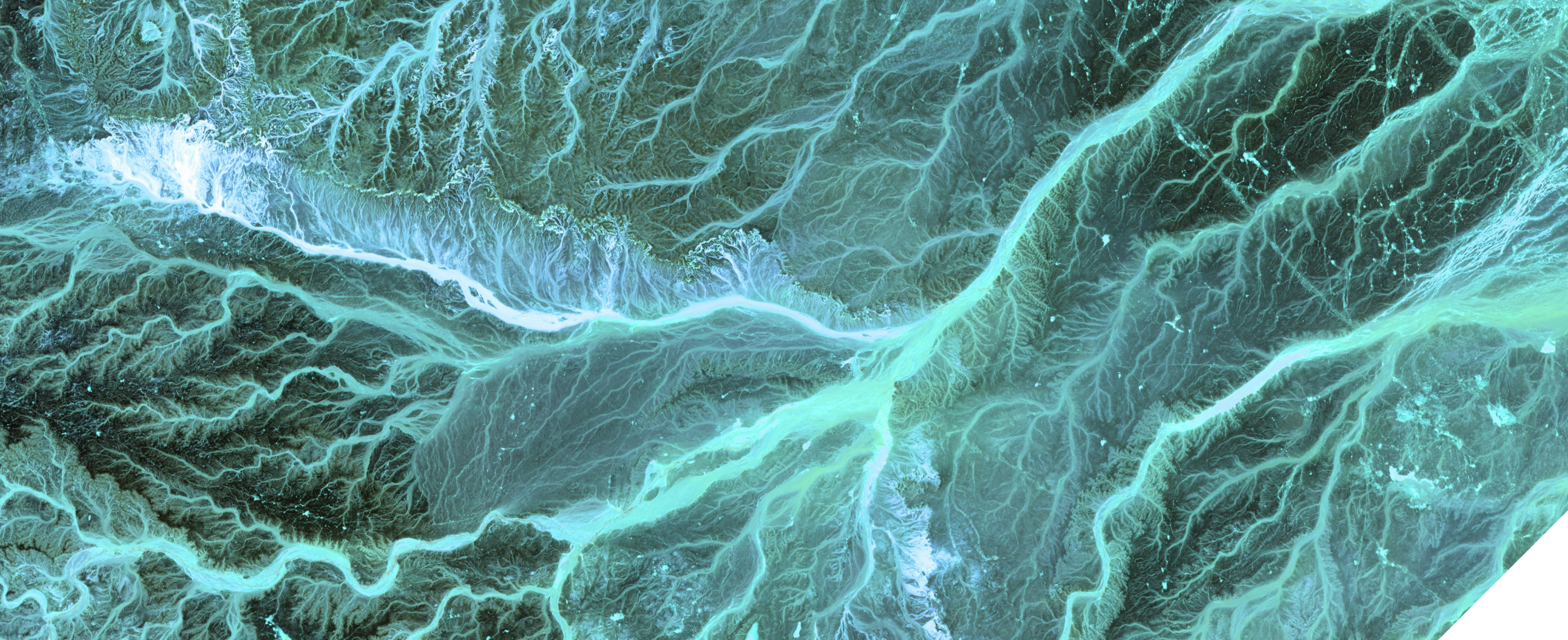

Material Mapping

We analyse your backfill process variability...

Real-Time Slack Flow Detection

Automated detection using SCADA pressure sensors...

Stope Fill

A free backfill design tool for visualisation and optimisation. Download:

StopeFill 1.2 (Download)