Retic Router

Retic Router (View Demo)

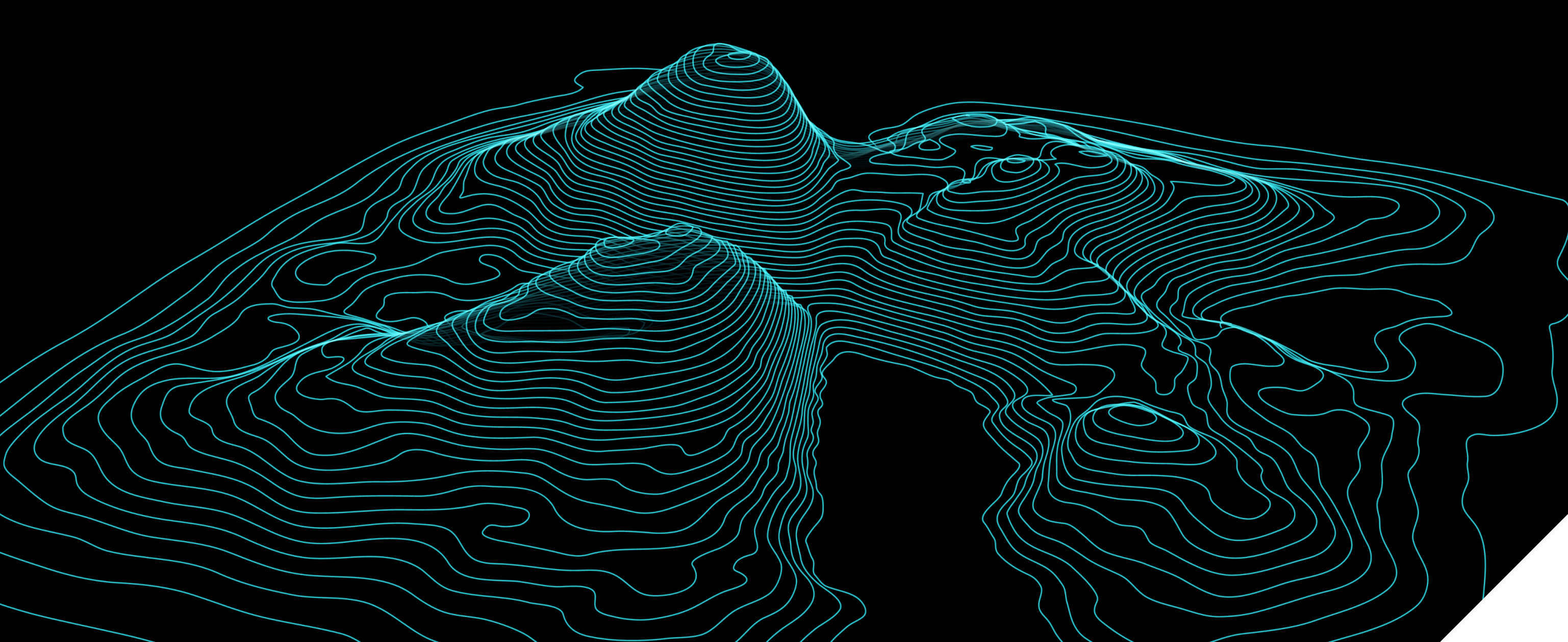

Stages of Design

- 1 Import your entire mine design...

- 2 Analyse stope solids...

- 3 Automatically develop a branched network...

- 4 Run dynamic hydraulic tests...

- 5 Generate a report with design recommendations...

Retic App

Retic App (Visit Site)

is a centralised platform for managing and optimising backfill operations...

Key Features

- Retic View - Interactive 3D visualization environment for reticulation systems, enabling

- Pipe Track - Advanced pipeline management system with wear monitoring, hydraulic performance analysis, installation scheduling, and automated generation of bills of materials

- Crush Log - Secure cloud-based QAQC database

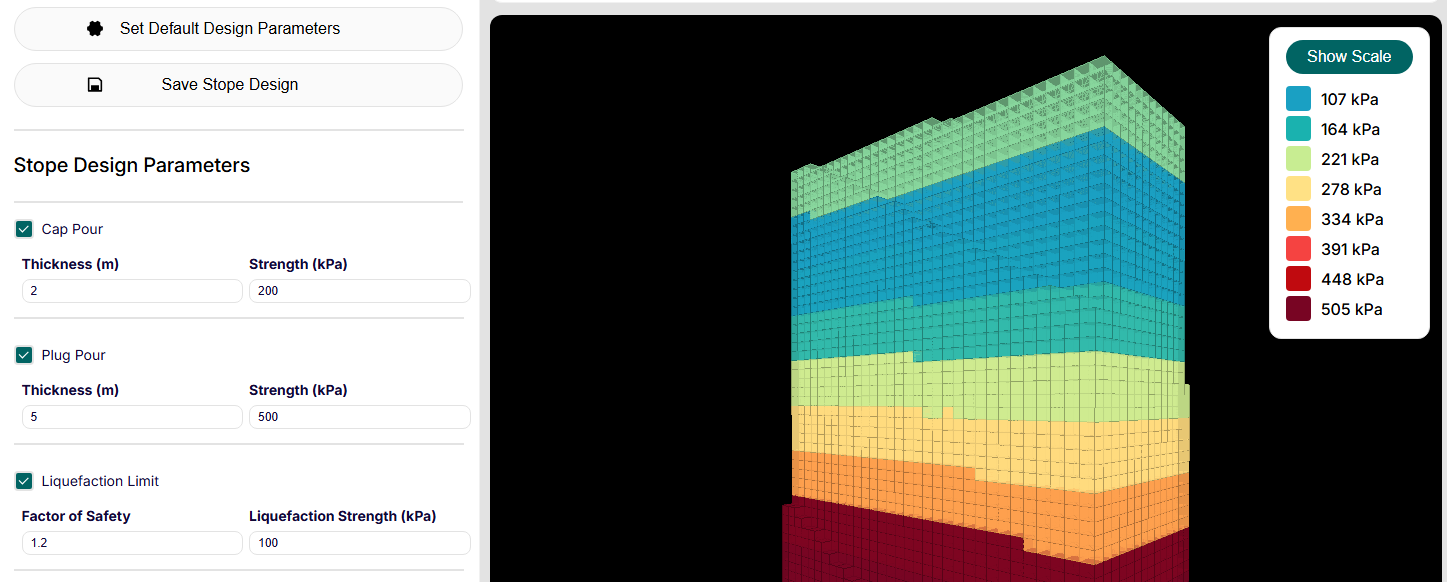

- Stope Fill - Analyse stope designs and create pour plans

- Paste Planner - Plan and schedule filling with Gantt charts

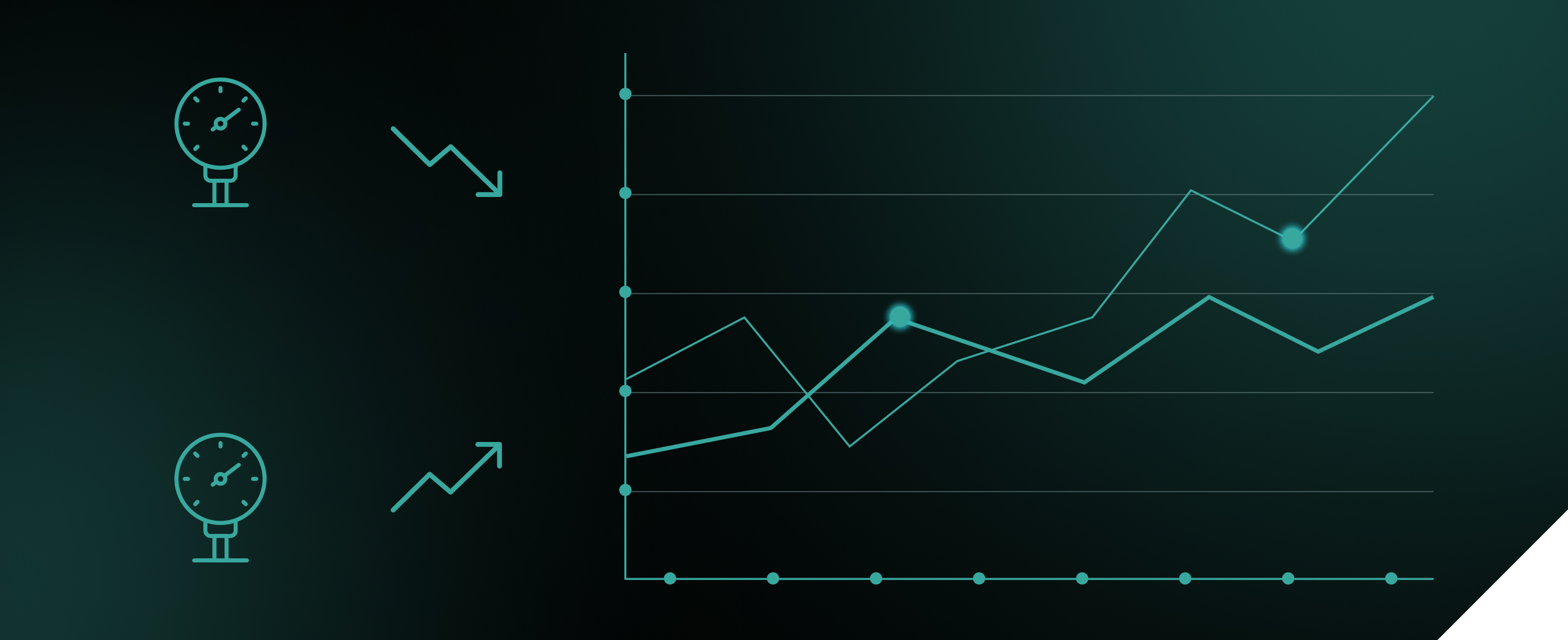

- Dashboard - Monitor performance and utilisation

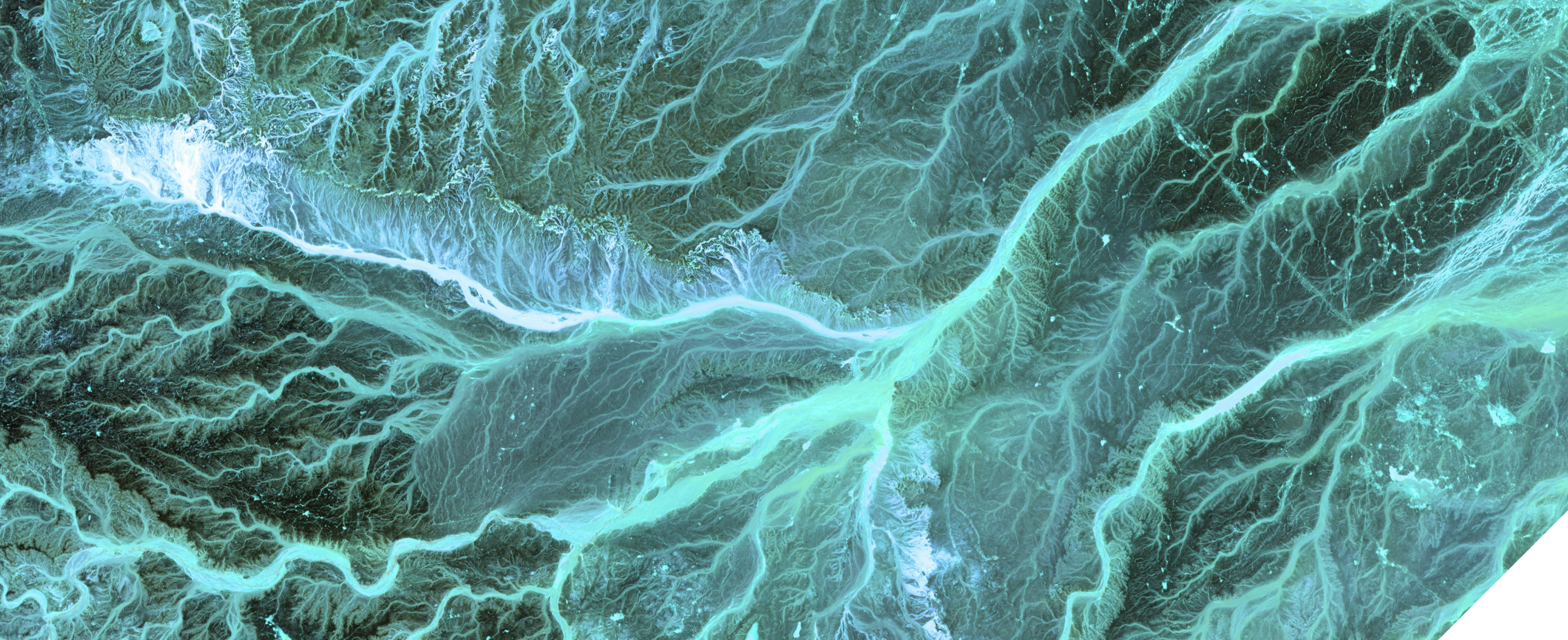

Material Mapping

We analyse your backfill process variability...

Real-Time Slack Flow Detection

Automated detection using SCADA pressure sensors...

Stope Fill

A free backfill design tool for visualisation and optimisation. Download:

StopeFill 1.2 (Download)